Almost every patient will lay on a foam support surface at some point during their hospital stay. They are an important component of patient care and need to be durable enough to withstand the rigors of day-to-day use and stringent cleaning protocols.

Despite their high use, foam support surfaces often go overlooked as a potential source of infection risk for patients. While it’s standard practice for these surfaces to be cleaned between uses, it’s not common for hospitals to look under the top cover to assess the condition and health of their foam support surfaces.

It’s also assumed that these high-use surfaces are durable and will last for a long time (at least five years). Unfortunately, they often wear out more quickly than expected. It does not take much for a foam surface to degrade, or for the tiniest of rips in the top cover to cause fluid ingress.

The result? Patients might unknowingly be resting on a compromised support surface.

Our latest case study, “Unique Support Surface Construction Materials Influence Fluid Ingress, Longevity and Return on Investment,” looks under the covers to explore this topic and showcases the stark differences between different foam support surfaces and how their construction, design and materials impact integrity and patient safety.

Why Foam Support Surfaces?

- Hospitals own many foam support surfaces, which are challenging to manage and costly to replace.

- Different agencies, including the U.S. Food and Drug Administration (FDA), The Joint Commission and the U.S. Department of Veterans Affairs (VA) have recently heightened their focus on the infection risk tied to foam support surfaces, prompting some facilities to require audits of their surfaces to ensure they are safe for patient use.

- Agiliti has been completing audits for years, typically when our customers notice that foam support surfaces are ‘damaged and cut’ or they even have a ‘distinct odor.’ In our audits, we regularly find mattresses that have been compromised due to fluid ingress.

As a result, we wanted to investigate the issue and better understand whether a surface’s materials and construction could decrease fluid ingress, cross-contamination and improve surface lifespan.

What The Study Revealed:

The study looked at 422 surfaces from multiple manufacturers, with an average age of six years. By assessing the different surfaces, it was shown that a lack of certain elements in typical foam support surface construction makes them more prone to damage and fluid ingress that requires replacement:

- Top Cover: Standard top cover fabrics are more quickly eroded by harsh cleaning chemicals, which degrades the natural ‘waterproofing’ that prevents fluid ingress.

- Sewing: Typical sewn seams create thousands of holes in the top cover which allows fluid to easily compromise interior components, including fire barriers.

- Lack of Welded Shield: In the study, 374 surfaces did not include a welded shield. Of those, 85% (318) sustained internal damage and required a full surface replacement. The 37 surfaces that included a welded shield showed no internal damage and did not require replacement.

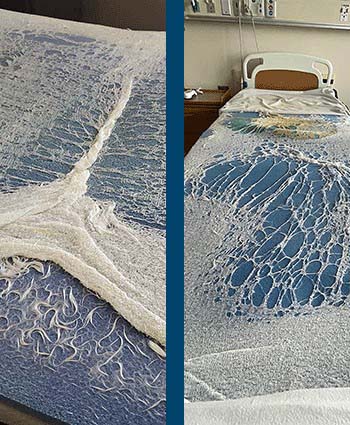

Examples of the damage seen with typical support surface construction:

Construction: Top cover material is eroded by harsh chemical cleansers

Result: Degraded waterproofing material allows for fluid ingress

Construction: Sewn seams create thousands of holes in cover

Result: Holes allow fluid to permeate the interior components

Construction: Fiberglass fire barrier breaks down over time and is chemically treated

Result: No longer offers fire protection

Construction: Unprotected interior components

Result: Fluid ingress and contamination of interior components, requires full replacement of the surface for patient safety

The study also highlighted specific construction details that helped prevent foam support surface damage, fluid ingress and preserve integrity:

Construction: Specially formulated top cover fabric

Result: No delamination of waterproofing, maintains integrity, and no fluid ingress

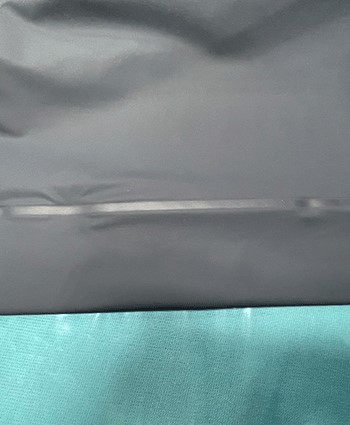

Construction: RF-welded seams permanently bond the material on a molecular level

Result: Avoiding holes to join fabric prevents fluid intrusion

Construction: Fiberglass-free fire barrier

Result: Remains intact over time ensuring adequate fire protection

Construction: Welded shield protected interior components

Result: The welded shield prevents fluid ingress to interior components if top cover would get damaged, further preventing full replacement

The Bigger Picture: Why It Matters

The key takeaway from the study is that most foam support surfaces in hospitals today are missing some important design and construction elements. What this means for your facility and patients can be categorized into three areas:

- Infection Control: Surfaces constructed with advanced materials, RF-welded seams and a welded shield help protect the internal components of the surface from fluid ingress. This proactive approach to infection control can reduce the risk of cross-contamination and healthcare-acquired infections.

- Extended Surface Lifespan: Support surfaces that are constructed out of the materials outlined above (top cover, RF-welded seams and welded shield) exhibit an extended lifespan. In the study, these surfaces did not require full replacement within the typical five-year span, indicating a much longer useful life. This longevity translates to fewer disruptions in patient care and savings over time.

- Cost Savings: Replacing a full support surface is significantly more expensive than replacing only the top cover. On average, the cost to replace one surface is ~$1,500, while a top cover replacement is ~$200. By opting for surfaces with the unique construction that prevents fluid ingress, as identified above, hospitals can drastically cut down on replacement costs. This not only preserves the budget but also allows funds to be allocated to other critical areas, ultimately enhancing the overall quality of care.

So you may be thinking – what do I do now?

Step 1: Inspect your foam support surfaces:

- Round up a few foam support surfaces and unzip/take off the top cover – what do you see?

- Start with inspecting the top cover (exterior, interior) to identify any rips, tears or other damage.

- As you do so, make sure to inspect the fire barrier on the surface and take a close look at the foam.

- We recommend looking at 25% of your surfaces (a minimum of 10) from different floors/locations.

Step 2: Capture your findings, including:

- Details of each surface (brand/manufacturer, model and year it was manufactured)

- Photographs of the top cover, inside top cover, fire barrier and foam

- Take detailed notes on what you find during your inspection

Step 3: Share your results:

- It’s important to share your findings with a trusted supervisor/leader and discuss potential next steps.

- This could include auditing more surfaces, replacing the top cover or a full surface replacement of compromised support surfaces.

- If replacements are needed quickly, you can complete this form to access product examples that meet the criteria discussed in the case study.

While completing an audit can seem like a lot to add to a busy plate, it’s a worthwhile practice to ensure you have visibility into the condition of the foam support surfaces that go under patients. Unfortunately, as the study found, common materials used in foam support surface construction break down more quickly than expected, and even small rips and tears can have a big impact on the integrity of the surface.

If you are not sure where to start – or how to conduct an audit – download the guide below. Alternatively, we offer an online audit tool that can help guide you through the process. Or, offload the process entirely with Agiliti experts and keep your team focused on patient care.